In this article, we will delve into how temperature influences the 3D printing process and how we can adjust it to get the best results.

When we talk about 3D printing, temperature is one of the most critical parameters we must control (probably the most critical one).

In the end, it’s logical; we are depositing molten material. So temperature directly affects print quality, mechanical strength… and, ultimately, whether your part turns out well or like a mess 😜.

So let’s see how we can control this parameter and how it affects our 3D prints 👇.

Why is temperature important in 3D printing?

In an FDM printer, the filament is melted in the hotend (the hot nozzle) and extruded in layers to form the final part.

If the temperature is not right, all kinds of problems can arise. Let’s look at some of them:

Temperature too low

If the temperature is too low for the material being used, several problems can arise, such as:

- Poor layer adhesion: The filament may not melt enough, resulting in weak adhesion between layers, causing the part to be fragile and susceptible to delamination.

- Inconsistent extrusion: Low temperature can make it difficult to extrude the filament, creating a rough and uneven surface on the part.

- Extruder clogging: When the filament does not melt completely, it can accumulate in the extruder, causing jams and print failures.

Temperature too high

On the other hand, a temperature that is too high can also cause problems, such as:

- Overheated filament: If the filament is heated excessively, it can become too liquid, causing issues like strings and oozing (stringing) on the part.

- Warping or deformations: If the temperature is too high, the material can cool unevenly, causing warping in the part.

- Surface defects: High temperature can cause bubbles, burns, or marks on the part’s surface, affecting both its appearance and structural integrity.

Material temperature

One of the reasons we usually forget that temperature is the most important parameter in 3D printing is that the range depends on the material we are using.

Each material has an optimal temperature range for its extrusion. Here is a list of the most common filaments and their recommended temperatures:

That is, we basically have the temperature constrained to a range depending on the material. So it seems we don’t have much room for maneuver.

But believe me, a 30° difference is having a lot of room for maneuver.

Fine-tuning the hotend temperature

Recommended temperatures are a good starting point, but each printer and each roll of filament can have small variations.

Therefore, it is advisable to perform temperature tests to find the optimal value.

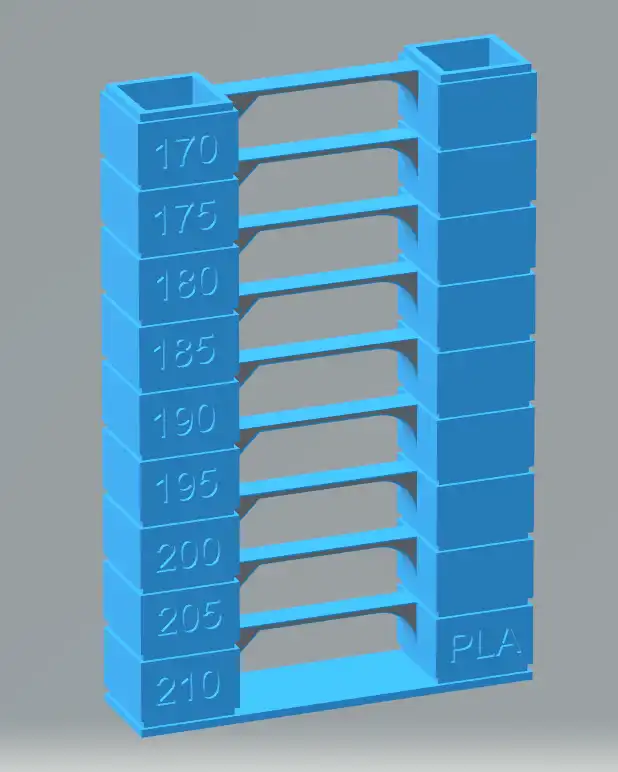

A common way to do this is to print a temperature tower, which is a model that changes the hotend temperature on each layer.

This way we can see how temperature affects print quality and choose the temperature where we see the fewest defects (like stringing, bubbles, or poor adhesion). This allows us to see how temperature affects print quality and choose the best option.

Ambient temperature

Although not always considered, ambient temperature can also affect 3D printing.

In cold environments, the filament can cool too quickly, which can cause adhesion problems and warping. On the other hand, in very hot environments, the filament may not solidify quickly enough.

You might say, “Well, but I can’t control the ambient temperature.” No, that’s why it’s not a good idea to put a 3D printer outdoors 😜.

There are various measures we can take to try to minimize the impact of ambient temperature on our 3D printer. Some of them are:

- Choose a suitable location: Such as a climate-controlled room, without too many drafts or humidity.

- Enclosed printers: It is always advisable to use an enclosed printer or build an enclosure to maintain a stable temperature.

- Away from heat and cold sources: Make sure the printer is not exposed to heat or cold sources, such as next to a radiator, windows, or air conditioning.