We continue with the 3D design and printing section, seeing a debate as controversial as a debate about which superior is better: direct or bowden printers?

The last entries have been devoted to see the operation of an FFF 3D printer, its kinematics, and the parts and components that compose it.

In them, we have seen that the “grace” of our 3D printer is to position the extrusion head with respect to the print bed precisely. We have also seen that the material to be melted is introduced into the extruder head.

If you are observant, you will see that in some of the schemes and images that we have already seen, the extruder appears just above the hotend, while in others, it appears in the structure.

Well, this is precisely the difference between a direct printer and a bowden printer. And, of course, each of these configurations has its own advantages and disadvantages, as well as its defenders and detractors.

As it is a frequent and interesting debate, and a question that is often asked in the world of FFF 3D printing, we are going to dedicate an entry to see the differences between both technologies.

Difference between direct and bowden

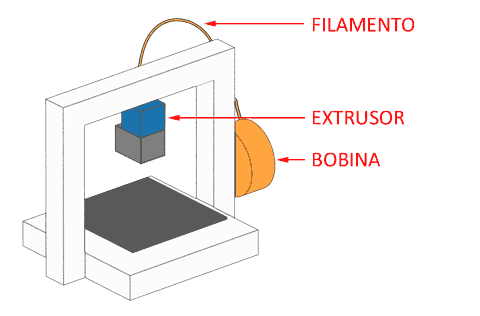

Direct printers

In a direct printer, the extruder is located right above the extruder head, on the same mobile carriage, moving solidarily with it.

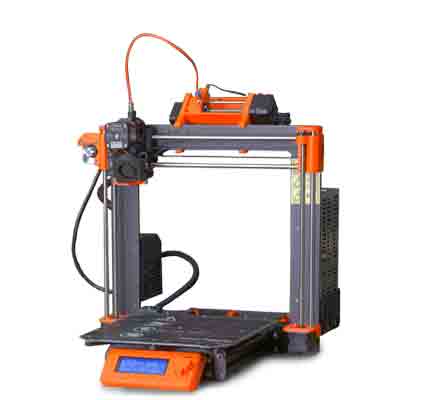

An example of a direct printer is the popular and well-known Prusa Mk3, in which we see the extruder motor is mounted right above the head.

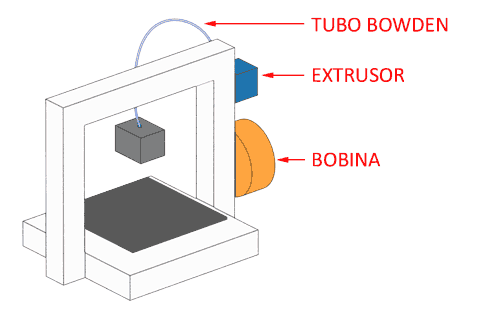

Bowden printers

On the contrary, in a bowden printer, the extruder is located in the structure. The filament is guided from the extruder to the extruder head through a plastic tube called (guess) bowden tube.

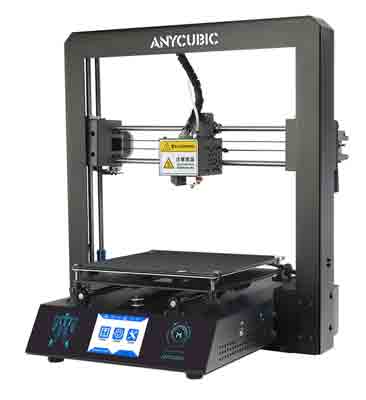

An example of a bowden printer is our beloved Anycubic i3 Mega, which we already saw some time ago in this post.

As we see in the image, the carriage does not contain the extruder, and instead it is located to the right, on the frame of the printer.

In reality, direct printers also have a “small bowden tube” to guide the filament between the end of the extruder and the head. But the length is only a few centimeters, so it really has no effect.

Advantages and disadvantages

As we said at the beginning, each configuration has its advantages and disadvantages, which leads to debates about which is better. In reality, these advantages are quite simple, and can be summarized in whether it is better to have better control over the filament, or to have less moving weight.

So, direct printers have the advantage of having greater control over the filament, because the extruder is right above the head and does not have to “deal” with a long piece of filament moving inside the bowden tube.

This translates into an ability to print smaller and finer details, and greater ease in avoiding certain typical problems in printing, such as the problematic oozing (fine strings that appear in the pieces).

On the other hand, bowden printers have the advantage of not having to move the weight of the extruder. In this way, the mobile carriage only has to move the print head, while the weight, especially of the extruder motor, is transferred to the structure.

This implies that the head will withstand lower vibrations and, in theory, we can have higher printing speeds. It also allows the use of lighter chassis and mobile components.

Finally, in the case of printers with multiple filaments, they generally have a bowden type configuration. Otherwise, the weight and size of several extruders on the carriage would be more problematic.

Conclusion

So, in short, which is better: direct or bowden? The summarized version is that most users prefer direct printing. Greater control of the filament compensates for the possible loss of speed.

However, as is often the case, the answer is not as simple as saying “direct good, bowden bad”. Let’s take the famous Ultimaker as an example, which is of the bowden type, and whose quality is hardly questionable.

In general, the results of a printer depend on many factors, with the configuration being one more factor. For example, the design of the printer, the robustness of the structure, or the quality of its components greatly influence.

And you, what do you think? Do you have a bowden or direct printer? Do you prefer any particular type? If you want to give us your opinion, you can leave us a comment!