New entry in our 3D design and printing section, and the last of this series dedicated to knowing in detail the components of a FFF 3D printer, which this time we will dedicate to the extruder.

We have already seen the main components of a FFF 3D printer and the parts that make it up. We have also seen in detail the extrusion head and the hotend. Now it’s time to see the extruder, which as we have seen is the element that is responsible for introducing the filament into the hotend in a controlled manner.

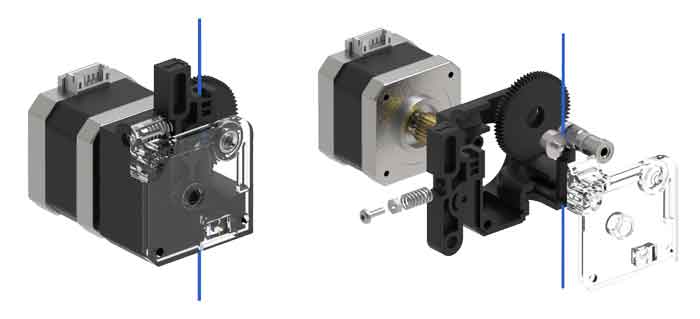

We already saw that, depending on whether the printer is direct or bowden type, the extruder will be located, respectively, in the extrusion head itself or on the structure.

Regardless of its position, the behavior and composition of the extruder are similar. The only difference is that, in the case of bowden printers, the filament will reach the hotend through a longer tube.

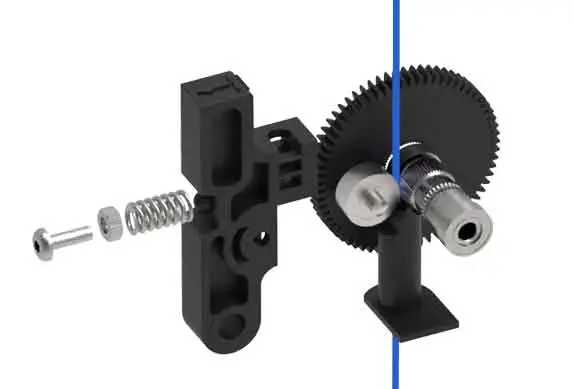

Basically, the extruder is formed by a Nema 17 type stepper motor, and a series of gears and wheels that are responsible for “grabbing” the filament and introducing it. Normally, the filament is trapped between a smooth bearing and a toothed wheel. When the toothed wheel rotates, it displaces the filament.

For the set to work correctly the gripping pressure on the filament must be adequate. For this, there is usually some kind of mechanism with a spring, whose force is controlled, for example by adjusting a spring.

If the pressure on the filament is insufficient, it can slide and we would introduce less material than the software expects. If it is excessive, we run the risk of breaking the filament, especially when the software has to pull out and put in material several times (we will see this when we talk about retraction).

As for the motor, it has slightly different requirements than the rest of the printer. In general, it is required to exert more force. If not, we may risk losing steps, and having an incorrect print.

Frequently, we will adjust the printer motor driver to allow higher current than the rest. But that implies greater heating. Fortunately, the speeds are small, although it is possible that we see some printer model that incorporates a heat sink to the extruder motor.

On the other hand, the extruder motor also needs to have greater precision (even) than the movement motors. That’s why it is also common to see motors with 400º steps per revolution, instead of the traditional 200º.

Finally, in direct type printers, the weight of the motor must be moved by the head. In this case, it is convenient for it to be as light as possible. Pancake type motors are often used, which are narrower and lighter.

For now, we have finished with this quick guide on the elements that make up a FFF 3D printer, and its functionality. In the next entry in the 3D printing section, we will continue to delve into this fun world by looking at 3D printing materials. See you soon!