We continue delving into the world of 3D design and printing, and dedicating a series of entries to see how a 3D printer works, its different parts, and components.

We already said at the beginning that, following the blog’s custom, we were going to start from the beginning. Because you don’t want to print without knowing what and why you are doing it. Right? You want to become 3D experts!

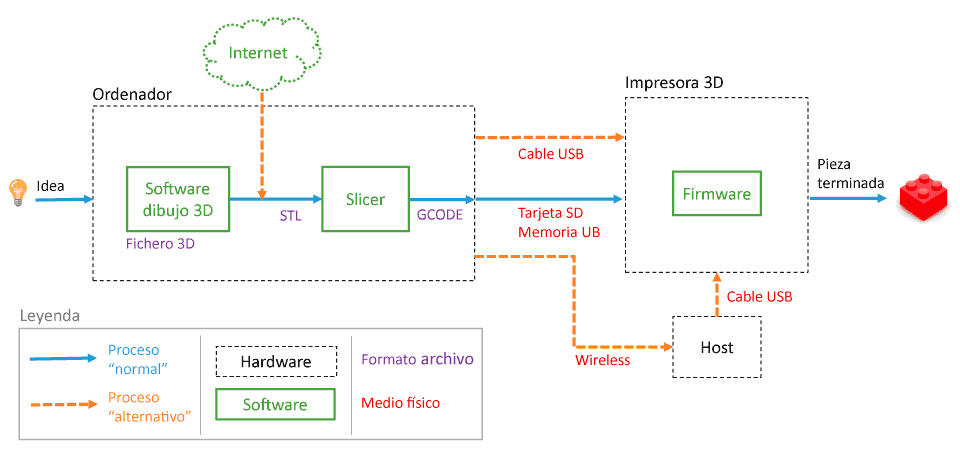

So, we have seen from the basics the representation of 3D objects on a computer. We have also seen the general 3D printing process, exploring the 3D design software, CAD software, the role of the slicer, and what the G-Code is.

Well… Finally, the time has come to start melting plastic! That is, to familiarize ourselves with an FFF 3D printer, and see how it works and why it is like that.

FFF 3D printers are the most common type of printers in the home and #maker field. Although stereolithography or resin (SLA) printers are also becoming more common.

For now, we will start with FFF 3D printers, and we will leave SLA 3D printers for the future. But, except for having differences, many of the concepts we are going to see are common to all types of 3D printers.

FFF 3D Printers

As its name suggests, a fused filament fabrication printer (FFF) generates 3D models by melting a filament (you saw it coming, right?)

FFF printers are also called fused deposition modeling (FDM) printers. However, FDM is a trademark of Stratasys Inc, so we will prefer to use FFF.

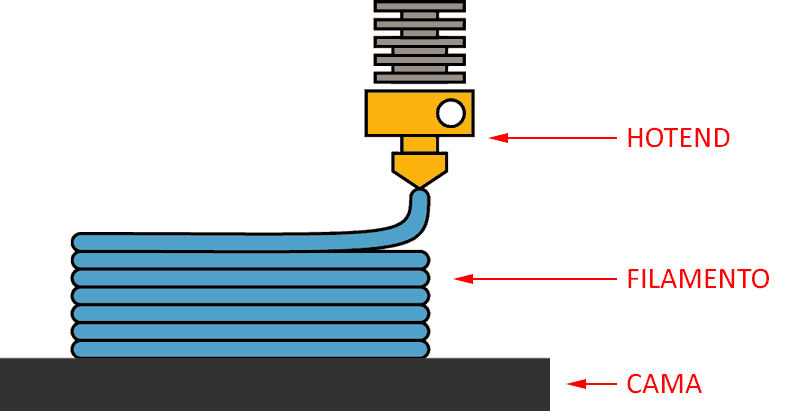

A hotend melts the filament, which is supplied from a coil. The melted material is deposited on the previous material, where it cools and solidifies to achieve our piece.

The filament has a diameter, with 1.75 mm being the most common, and, to a lesser extent, 2.85mm. It is necessary for the diameter to be precise and constant because it is used by the calculator to calculate the amount of material deposited in each case.

On the other hand, the hotend also has a nozzle diameter, which is the diameter of the melted filament that we are going to deposit. The most common size is 0.4mm, although it is easy and cheap to change the nozzle for others from 0.2 to 1mm.

The entire piece is printed on the print bed, a flat surface that serves as support for the pieces we print. Generally, the bed is heated to facilitate the adherence of the deposited material.

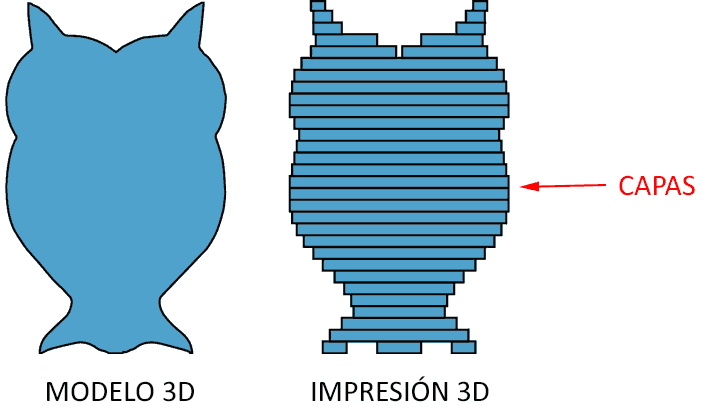

As we can see, the piece is printed in layers or “slices”. Each slice is formed by the intersection of the piece with the plane parallel to the bed at that height. Calculating these sections and the movements to print each layer is the role of the slicer.

Each layer that makes up our 3D piece is printed on the previous layer, except for the first one, which is printed on the bed itself. The adhesion of the first layer is always a critical point, which we will also see in due time.

The thickness of each of the layers is a very important parameter in 3D printing. We will delve into this in its own entry, as well as each of the points we have seen in this post.

But first, we will continue to see how our 3D printer works. As you can imagine, most of the “trick” of the printer is to precisely position the head relative to the print bed.

We will dedicate the next entry precisely to this, seeing how the kinematics of our 3D printer works. See you soon!