We continue with the design and 3D printing section, delving into CAD programs with this introduction to CAD program management.

In previous entries, we have already seen the main types of programs for 3D drawing, and the main existing CAD programs, highlighting those that are Open Source or free, which are the ones we will normally use in the Maker environment.

As we said, it’s finally time to enter CAD programs, which is the main type of 3D software that most of us will use most of the time for designing parts (unless you are in fine arts and know how to draw or sculpt the head of a dragon).

To that end, we are going to introduce the philosophy and generalities of CAD programs, presenting some concepts and terms commonly used in the field.

It is worth noting that we will not focus on any specific CAD program. First, because there are many CAD programs, and you will surely find hundreds of tutorials and documentation for each of them.

We don’t want that. What we want is to get a “feel” for the 3D world and learn to use CAD programs, not just ONE CAD program. And that’s because, fundamentally, the philosophy and concepts behind all of them are the same.

Of course, each program will have its own peculiarities. But in most cases, the operation of all of them is very similar. If you know how to use one CAD software, switching to another is not a matter of “how the heck do I do this” but “where is the button that does what I want to do”.

So, we are going to present the general philosophy of CAD software and the terms we will encounter when we open any CAD software. And then, everyone can use the one they like the most, have available, or know how to use.

CAD Design Elements

Typically, in CAD programs, a distinction is made between parts, assemblies, and drawings. In many cases, different file extensions are available for each of them, although not in all cases.

Next, we will take a look at each of these elements.

Parts

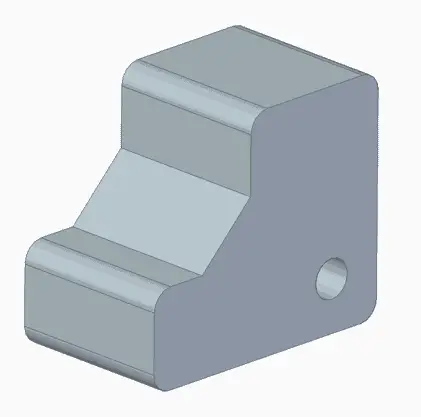

The part is the fundamental component of our designs. They represent the abstraction of a unique object, and correspond to a physically fabricable part.

Therefore, in general, and with few exceptions, they will consist of a single connected volume. In addition, they will have a material, and physical properties such as mass, center of gravity, inertia axes, etc.

During the 3D design, a very important part of our time will be spent drawing and modifying the parts. Most of the time, we will start from a 2D drawing and convert it into 3D using solid or surface operations. We will see this in more detail below.

2D Sketch

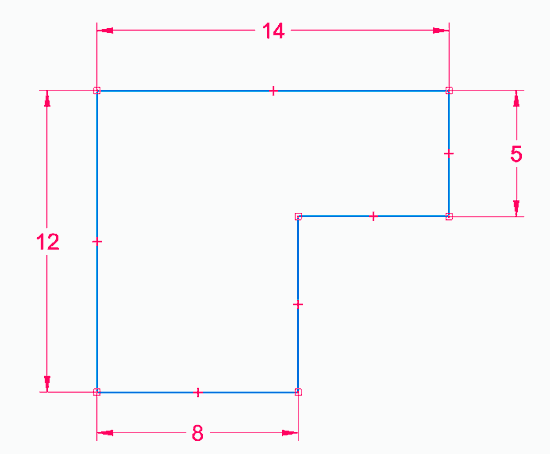

In CAD programs, the 2D part of the design is generated using sketches that we create on a reference plane.

The entities we draw maintain relationships and constraints between them. Such as being horizontal/vertical, parallel, perpendicular, concentric, etc.

The dimension of the elements is also considered a constraint. Therefore, sketches are usually drawn “approximately” without paying special attention to the size, and subsequently dimensioned through constraints.

If you are used to technical drawing programs like AutoCAD, where entities are drawn directly with their dimensions, you might find it a bit difficult to get used to this way of drawing (don’t worry, we all went through it).

3D Operations

The next step is to use the 2D sketches to generate 3D solids through operations. There are many operations that we can use, although we will see that in reality there are not as many as they seem at first.

Knowing the available operations and mastering their use is key to using a CAD software, and even more so for using more than one CAD. Given its importance, we will dedicate the next post exclusively to see the 3D operations available in CAD programs.

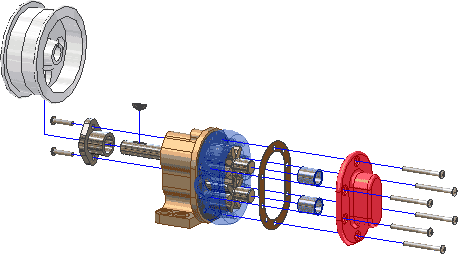

Assemblies and Subassemblies

Once we have the parts, it is common to combine them into an assembly or subassembly. For this, position constraints are used, such as coincidence, contact, insert, and many others like axis on plane, cam constraint, helical constraint.

The list of parts and the quantity constitute the “Bill of Materials”. This is an important element as it represents the list of components necessary to manufacture the object, and is closely related to the part’s budget, stocks, links with the ERP, etc.

On the other hand, in many cases we can leave some of the parts not totally restricted, so they retain some degree of freedom. This allows us to animate or simulate the kinematics of the assembly.

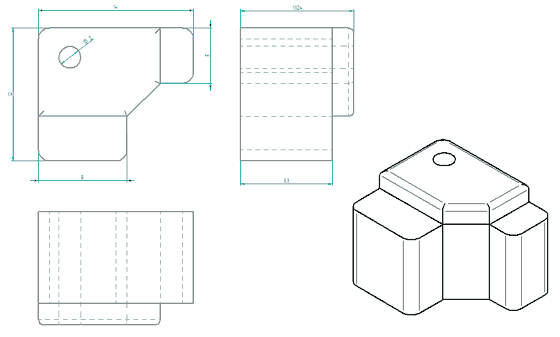

Drawings

Finally, CAD programs allow us to create 2D drawings and representations of the parts and assemblies we create. The process is very similar in all CAD programs.

First, there are tools to add a main view of a part or assembly according to some orientation. Subsequently, we add auxiliary views, sections, cuts, details. And on them, we dimension, add symbols, or annotations.

In the maker field, in general, this functionality may not be so widely used. Even in the professional world, there is a trend to disappear in favor of manufacturing with 3D viewers.

Parametric Associative Design

Perhaps the most outstanding feature of CAD programs is their associative and parametric nature. In fact, on many occasions, we refer to CAD software as “associative drawing” or “parametric drawing”.

This means that all operations maintain a dependency on the previous ones. In this way, if we modify a previous operation, all subsequent operations are maintained and reflect this modification.

Logically, for this, the modification must allow the subsequent operations to remain valid. For example, if we chamfer a hole and then modify the hole, the chamfer operation becomes “lost” and is no longer valid.

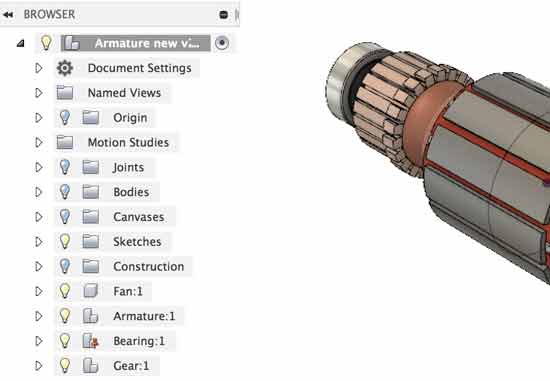

Operation Tree

In practically all CAD programs, operations are reflected in order in an operation tree.

In this way, we can comfortably visualize the steps that the design has undergone and their dependencies. This allows us to modify operations, return to previous states, or even temporarily deactivate an operation.

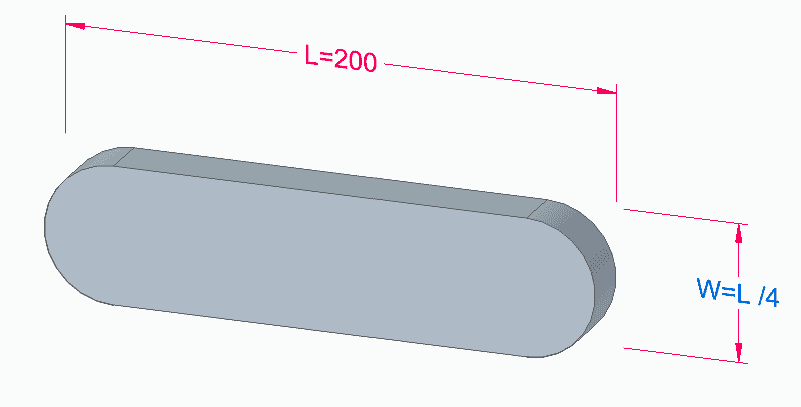

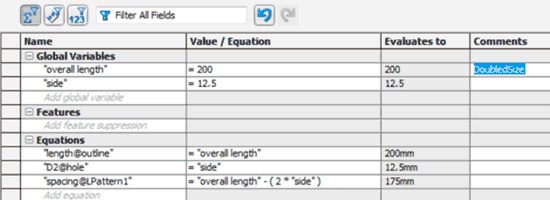

Variables and Parameters

The other related and common feature in CAD programs is the ability to define variables and parameters in the parts.

For example, in a part, instead of creating a 100 mm long part, we can define a variable L, and use this value as if it were a numerical value.

At any time, we can modify the value of this variable and the entire design will change accordingly.

On the other hand, we can define relationships or equations between variables. This allows us to give a certain “intelligent” behavior to our designs, facilitates their modification, and helps eliminate errors.

Additional Features

In addition to these “traditional” features, most CAD programs have evolved to incorporate more advanced features that facilitate part design.

These features are becoming more and more frequent (or even common) in CAD, so we will review some of these concepts so that you are not caught off guard when you encounter them.

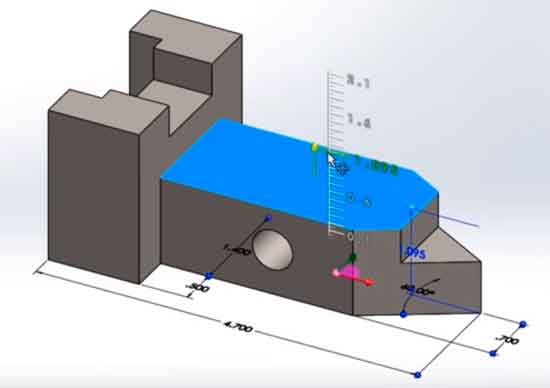

Direct Modeling

One of these features is the ability for direct editing, understood as the possibility of modifying a part simply by clicking on a face or operation and dragging.

For example, we have Instant 3D in SolidWorks, synchronous mode in Solid Edge, or Direct 3D in Inventor. Although each software incorporates direct modeling with its own particularities.

Design from Assembly

A basic functionality of any modern CAD is the ability to create parts directly from an assembly. This makes it easier to create parts quickly, especially when they are related in an assembly.

These parts can either be published as a regular part file or, in some cases, remain “embedded” in the assembly without having their own file.

Another common need is the ability to create relationships between parts through their assembly in an assembly. For example, we can project elements of one part onto another, to perform machining in the correct position to fit with another.

This creates dependencies and relationships between the part files, so, although it is very useful, care must always be taken when using them.

Adaptive Parts

The concept of adaptive parts refers to a part that can be inserted into an assembly and modify some of its parameters. This variation of the parameter is done without modifying the original part, nor the need to create a separate file.

Examples of implementations in CAD include adaptive parts in Solid Edge or iParts in Inventor.

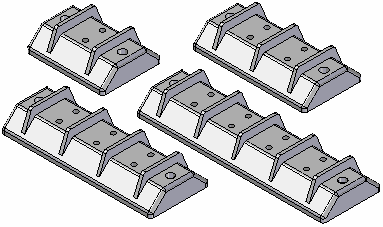

Part Families

Related to the previous feature, and in a way, completely contrary. Part families are several files that are generated by varying one or more parameters. In this case, each variation generates its own “child” file.

Part families are used to quickly generate similar elements, for example, those with varying nominal length.

In addition, they allow these parts to be maintained more easily. To make a modification, we only modify the “parent” file, and depending on the CAD, either regenerate the child files, or they are updated automatically.

As examples of implementations, in Solid Edge, they are called Part Family, or in Inventor, they correspond to iAssemblies.

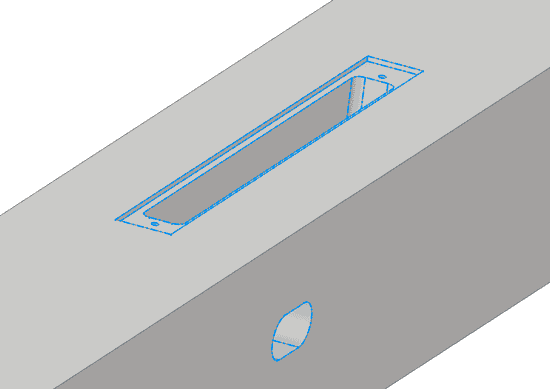

Associated Operations

Another common feature is the ability for one part to perform operations on others. For example, it is useful for parts such as inserts that require machining for their assembly, or to avoid repeating frequently performed machining operations.

For example, we have Library features in Solid Works or iFeatures in Inventor.

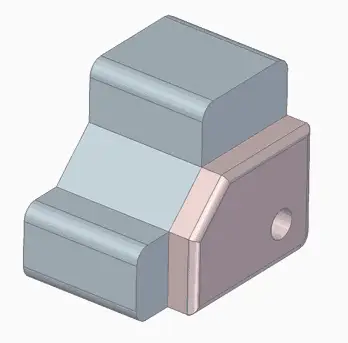

Multibody/Multipiece

An increasingly common feature is multibody or multipiece design. It consists of having several independent volumes within the same part file.

This allows them to be quickly drawn using the available part operations. Subsequently, the multipiece objects are published, and a part file is generated for each body, and an assembly file that assembles them according to the original arrangement.

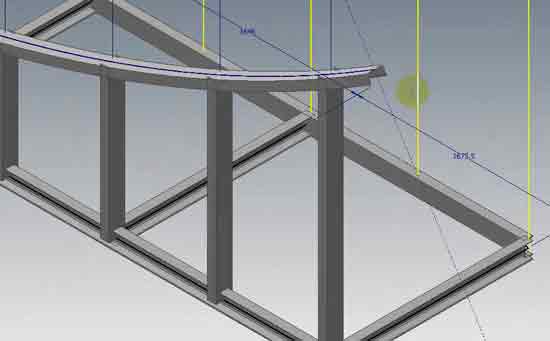

Multibody design represents an improvement in speed in cases of assemblies with a large number of parts with a great relationship between them. For example, in structures of welded profiles.

Conclusion

In this post, we have seen some of the fundamentals of CAD design. Knowing these concepts will allow us to handle one or several CAD programs easily.

We have seen the main traditional features of CAD programs, such as the meaning of associative and parametric design, or the workflow of 2D sketch, 3D operation, part, assembly.

In addition, we have reviewed some common functionalities and terms in many CAD programs, such as direct design, design from assembly, or working with multibodies.

In the next post, we will delve into the 3D operations available in solid design, and that we will find in CAD programs. See you soon!