In the two previous posts, we saw the criteria to consider when choosing an actuator or motor for use in our Arduino projects, and the main types of rotary motors available, with their advantages and disadvantages.

We conclude the selection guide by looking at the main types of linear actuators available, with their operation, characteristics, advantages, and disadvantages.

The explanation of how each type of actuator works will be quantitative and without equations, as going into details for each one would fill a chapter of an electronics book. The goal is to explain in a simple way how they work and their advantages and disadvantages.

Electromagnets

An electromagnet is a device that allows attracting ferromagnetic objects, such as Fe and some of its alloys.

An electromagnet consists of a coil wound around a ferromagnetic core. When a current is applied to the coil, a magnetic field is generated inside it, which creates an attractive or repulsive force on other materials.

The ferromagnetic core of the electromagnet increases the power of the magnetic field and reduces losses due to dispersion.

We can use an electromagnet in our projects to create a small crane, or installed on a robotic arm to lift objects, or even to fix a robot to a metal plate.

Magnetic Actuators

Magnetic actuators are similar to an electromagnet, but the magnetic core is movable. At the end, there is often a plastic piece, for example, with a small clamp.

When current flows, the core is attracted into the interior of the electromagnet. A spring is provided to return the internal pin to its original position when the current stops.

This type of magnetic actuator is very commonly used. They are very fast, but have the disadvantage of having a small stroke.

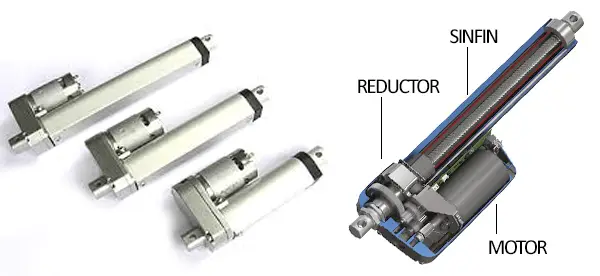

Linear Actuators

Linear actuators consist of a DC motor and a rod actuated by a worm screw, inside a compact integrated unit.

This type of actuator is available in a wide variety of lengths, some of them very long. They are capable of exerting large forces. The drawback is that they are quite slow devices.

This type of linear actuator is capable of moving heavy loads and is used, for example, to operate awnings, lift loads.

Motors with Worm Screw and Slider

Similar to the previous ones, these actuators also consist of a DC motor that drives a worm screw. But in this case, there is an intermediate element that moves along the stroke.

The slider is keyed so it does not rotate with the screw. This keying can be via one or several guides, or side keying on one or both sides.

In this case, the actuator’s characteristics will depend on the motor used, which could be a DC motor or a stepper motor.

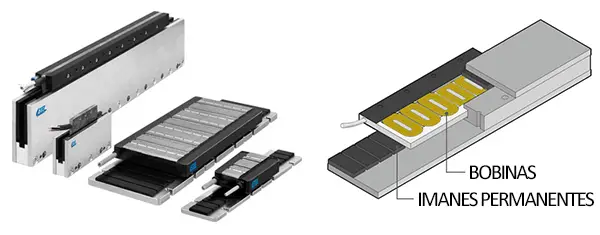

Linear Motors

Linear motors work similarly to a stepper motor, but instead of rotating a rotor, a slider is moved linearly.

They consist of one or several rails, along which magnets of alternating polarities are arranged. Depending on the motor typology, on, between, or around the rail, there is a slider with electronically controlled coils.

By varying the polarity of the magnetic field generated in the coils installed on the slider.

Linear motors have high speed, high torque, and high precision in movements. They are used, for example, as replacements for worm screw sliders in industrial CNC machines. You can also find them in maglev trains, and even in advanced weaponry like railguns.

However, linear motors have a prohibitive price for home projects. (If you ever have access to one of these, you can lend it to me, I’m eager to play with one

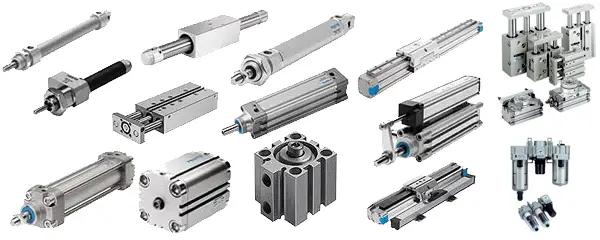

Hydraulics and Pneumatics

Of course, we couldn’t talk about actuators without mentioning hydraulic or pneumatic devices.

In these systems, a fluid (oil or water in hydraulics, air in pneumatics) is propelled along a series of tubes and actuators. Control is achieved by acting on the electronic valves located along the conduits.

Hydraulic systems are capable of exerting large forces with great precision. They are widely used, from excavators, presses, and all kinds of automation.

Pneumatic systems have less precision and force, as they work with gas which is a compressible fluid. However, they are faster than hydraulic ones. They are also widely used in industry, to operate tools, eject parts, or perform movements.

However, hydraulic and pneumatic systems generally require the use of expensive and bulky equipment, placing them out of reach for most home projects. Seriously, don’t try to use these systems if you don’t know exactly what you’re doing.

Summary Table

The previous information is summarized in the following table. Of course, it will depend on the particular model of each chosen motor, but in broad strokes and as a summary,

| Characteristics | Control (*) | |

|---|---|---|

| Speed | Force/Torque | |

| Electromagnet | – | ▲High |

| Magnetic actuator | ▲High | – Medium |

| Linear actuator (1) | ▼Low | ▲High |

| Linear actuator (2) | ▼Low | ▲High |

| Motor with worm screw and slider (1) | ▼Low | ▲High |

| Motor with worm screw and slider (2) | ▼Low | ▲High |

(*) With an encoder, all become absolute control of position and speed (1) Driven by DC motor (2) Driven by stepper motor

Conclusions

Most of the devices invented by humanity to generate movement are rotary machines. To generate linear motion, it is most common to use a rotary motor accompanied by some mechanism that converts the motion to linear.

The electromagnet is a simple machine that we can use to attract ferromagnetic objects and lift loads. They can exert large forces, but act over small distances. Furthermore, we have no control over speed or position.

Electromagnetic actuators use an electromagnet to attract a small actuator. They are very fast, but the action distance is very small and the force they can exert is usually small.

Linear actuators allow moving heavy loads and can have quite long strokes. In return, they are slow mechanisms. They can be combined with other types of mechanisms (levers, scissors, ball joints, etc.) to expand their range of action and speed, but decreasing the force exerted. They can be used, for example, to retract an awning, raise platforms, open a door.

Another common device is a motor with a worm screw and slider. In general, they have low speed, high precision, and high torque, although it depends greatly on whether a DC motor or a stepper motor is used. They are very common in linear applications requiring high precision, such as CNC machines or 3D printers.

Finally, linear motors are rare and extremely expensive. As for hydraulic and pneumatic solutions, they are only recommended for professionals and experienced installers, as they require a large number of elements and safety measures.