New personal weekend project, it’s time to keep playing with the M5 Paper and explore its visualization capabilities.

Last week we saw how to use the M5 Paper to display blueprints, extracted from an ERP/PDM/PLM or whatever acronym you want to use.

Visually displaying blueprints was a good test, as they are complex and demanding graphics. We must say that the M5 Paper’s electronic ink screen held up to the challenge with flying colors.

But we already said that a (good) trend in any modern factory is to eliminate blueprints. So let’s try to display manufacturing information in a more “4.0” way.

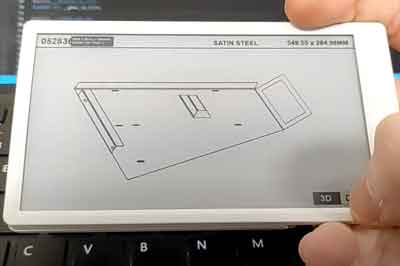

Here we have the result.

What are we seeing? First, we read a barcode from an application in C#. Obviously, this barcode could be a manufacturing order, warehouse order, purchase order, attached to a box, or whatever.

The application accesses the ERP/PDM/PLM/whatever database, downloads the manufacturing files, and sends the information to the M5 Paper. This, in turn, retrieves the information and loads it for display.

The information we show in this example is the development of a sheet metal part and its 3D representation, as well as additional data such as material, dimensions. Obviously, we could include stock units, destination, or whatever we wanted.

The development of the sheet metal part is obtained from the DXF and the representation is vectorial. Remember that a DXF is a text file that is easily interpretable.

In this example, for now, the 3D representation is a static image, which is adapted to the M5’s 16-level grayscale e-ink screen.

Pretty practical, right? And eye-catching, if I may say so. Next tasks, make the development view a canvas, that you can drag and zoom in on using the M5 Paper’s touch screen.

Next, make the 3D view of the part not a static image, but a 3D model that you can rotate, zoom in on, etc. And I’m really looking forward to this one because a 3D engine that works on an electronic ink screen is not something you usually see.

We’ll keep you posted on the progress, until next time!