We continue with the 3D printing design section by looking at the components of a 3D printer. This time it’s the hotend’s turn.

In the previous post, we saw the print head and its importance in the operation of an FFF 3D printer. As we saw, inside the print head is the hotend, which is the element that melts the filament and deposits it onto the part.

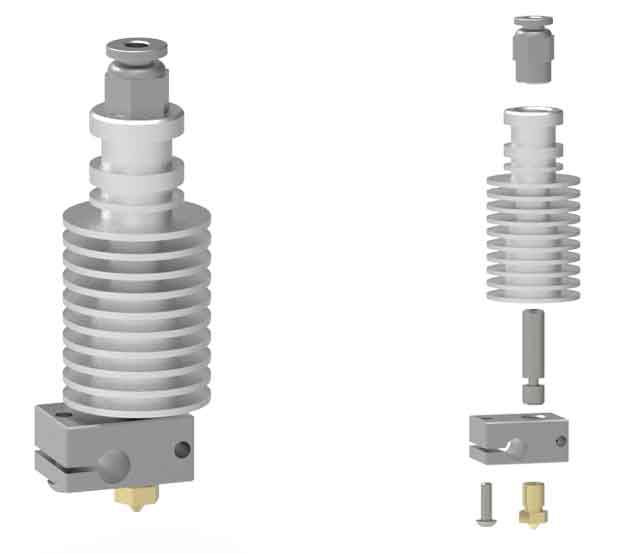

At the top there is a hole through which the filament is fed. If the printer is a Differences between direct drive or bowden 3D printers, there will be a push-fit retainer that holds one end of the bowden tube.

The material melting occurs in the lower prismatic metal block. A heating cartridge is housed in the larger hole and is secured simply with a screw.

It is important to maintain the appropriate temperature for the material we are depositing. Therefore, a thermistor is also housed in this block, which, along with the board’s electronics, is responsible for keeping the printing temperature constant.

The “ideal” behavior of the hotend would be to keep the filament cold right up until the moment it exits, maintaining the shortest possible length of molten filament.

To achieve this, the main body of the hotend consists of a finned heatsink through which air is circulated with a fan. This element dissipates the heat generated in the block and allows the material to reach the exterior without melting.

The block and the heatsink are joined by a heatbreak that has threaded ends on both sides, to which both elements are screwed. There are two types of heatbreaks: those with a plastic inner tube and those that are all-metal. In principle, heatbreaks with a plastic interior are less prone to clogs, while full-metal ones are necessary for printing high-temperature materials.

Finally, the extrusion nozzle is located at the bottom of the hotend. This element, usually made of brass, has a threaded end that connects it to the block.

The extrusion nozzle imparts the final dimension to the deposited filament, and therefore it is important that it is correctly and precisely machined. Nozzle diameters range from 0.1mm to 1.6mm, with the most common being 0.4 to 0.8mm.

Of course, there are many types of hotends available. Some of the most popular are the E3D V5 and V6, and their Chinese clones (of not as good quality). Although it is not the only type of hotend.

That’s all for this post on the hotend of an FFF printer and its operation. As we can see, it is one of the most important elements of a 3D printer. In the next post, we will look at the extruder.