We continue with the design tutorials for 3D printing, looking at the parts of a 3D printed piece.

We have already seen that during the printing of a piece in an FDM printer, the nozzle layers the piece layer by layer. But this does not mean that these layers are completely solid.

On the contrary, the printer takes advantage of the fact that it builds the piece by depositing material layer by layer to make partially hollow pieces. To do this, it “plays” with the paths and the degree of infill, depending on the part of the piece being printed.

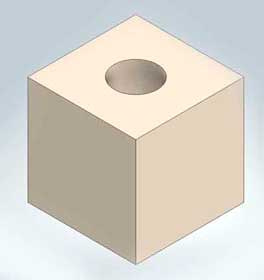

For example, let’s say we want to make this simple piece consisting of a cube with a through-hole. The slicer will treat each part of the piece differently, depending on its position in the piece.

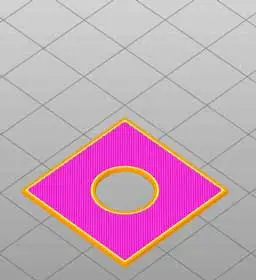

Thus, the printing begins with the lower parts of the piece being completely filled. In the next image, they would be the magenta lines. Normally, 2 to 4 completely solid layers are made in all the lower parts of the piece.

On the other hand, all the contours of the piece, both lower and upper, are made using several concentric paths. In the image, they would be the orange and yellow lines. Again, 2 to 4 concentric paths are used.

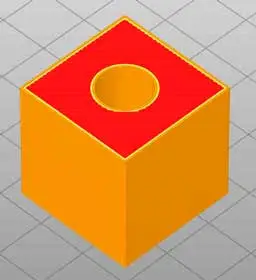

The rest of the piece, that is, the interior of it, is completed with a partially hollow infill pattern. In the next image, they would be the dark red lines. There are different possible patterns, with the most common being 45º lines, whose direction alternates between layers.

Finally, the piece is closed at the top with 2 to 4 completely solid layers, similar to how it was done at the bottom. They would be the red lines in the following image.

The reason for building the piece in this way is to form a “solid shell” with a partially hollow interior. This achieves a saving in material, weight, and printing time.

Additionally, due to the way materials work, this partial infill allows them to maintain their strength in a proportion greater than the reduction in weight. That is, a piece with 40% of the weight normally obtains a resistance superior to that percentage.

If you think this is a great idea, consider that nature is years ahead of us, and our bones are already formed by a porous pattern, surrounded by a solid exterior. This allows them to be lightweight, while being strong.

Now that we know what the parts of a 3D printed piece are, in the next posts we will see the main parameters that we can adjust in the slicer when printing a piece. This includes the infill factor, which controls the percentage of the piece that is “hollow”. But we will see that in the next post.