With the signs of improvement and progressive recovery of the global economy beginning to appear, gradually, new offers for incorporation into the labor market are emerging. Currently, within the field of engineering, one of the most demanded positions is that of process improvement expert.

It would be worth mentioning how curious it is that interest in improving productivity arises at the end of a recession. It would have been correct to make these improvements before or even during it. We should consider that we still have a terrible misunderstanding regarding process improvement. Precisely, the worse the situation, the greater the investment we should make in improving our efficiency to reduce costs.

In any case, it can be an overwhelming task, especially for novice engineers, to undertake a comprehensive process improvement in a small or medium-sized company that, due to economic circumstances, has halted or reduced its investment in process improvement.

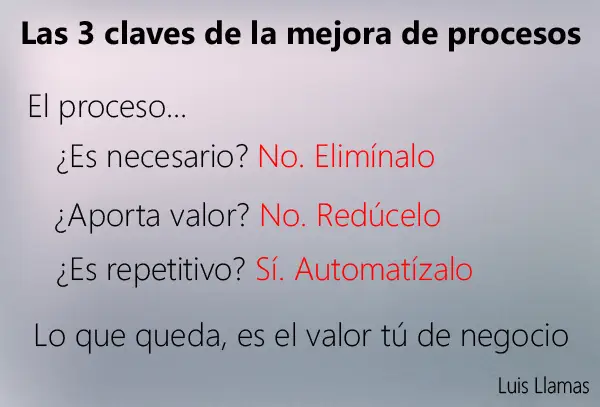

I share with you what, for me, are the 3 keys that guarantee success in process improvement.

- Eliminate unnecessary processes. Quite self-explanatory. If a process can be classified as unnecessary, it should not exist. If there is no reason for it to exist, it is a superfluous expense and should be eliminated. A clear example is much of the waiting and traveling, which can be eliminated with a redistribution of the productive space.

- Reduce processes that do not add value. Understanding the value of the product as what our customer would be willing to pay for, it is obvious that some of our processes do not add value, but we still need to do them. For example, office cleaning, or managing your MPR do not add value to the customer, but are essential for the proper functioning of the company. In these cases, these processes need to be located and minimized as much as possible.

- Automate repetitive processes. Automation is the best friend of process improvement. But not only in direct production processes. Automation must also be integrated in offices and, in general, in the entire workflow of the company, helping to reduce unnecessary bureaucracy and indirect expenses. Ultimately, any process that does not require creative skills or decision-making subject to unpredictable factors should be performed automatically.

These points are the direct result of the application of Lean Manufacturing practices, conveniently reduced and synthesized. They are 3 simple, easy, clear, and easy to understand and remember rules that should accompany you and become your best friends throughout the entire improvement process.

Of course, being easy to understand does not mean it is easy to put into practice. Rearranging space in a factory to improve versatility, reduce waiting times, and transport is usually manageable. Undertaking a comprehensive reform of a company’s workflow to reduce non-value-added tasks, eliminate bureaucracy, and automate processes… can be a titanic task.

However, keeping these 3 rules in mind and applying them properly at the right time will allow us to be a little closer to success.